OEM Services

- Home

- »

- OEM Services

- »

- stamping-product

HRS STAMPING SERVICE

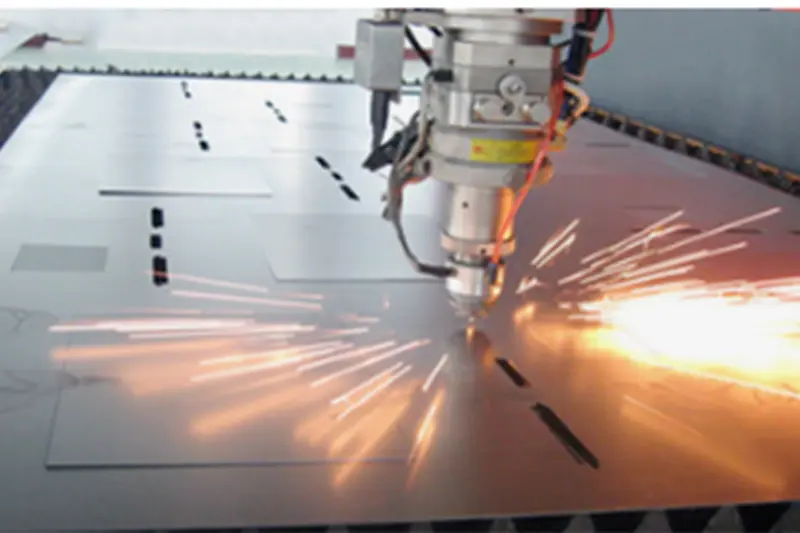

Stamping service is a crucial metal processing service that involves placing metal sheets, strips, tubes, etc., into the dies of a stamping press and applying external force to cause plastic deformation or separation, thereby obtaining stamping parts of the desired shape and size. Stamping services primarily rely on three key elements: stamping presses, dies, and stamping materials. The stamping press provides the power, the dies determine the shape and size of the stamping parts, and the stamping materials are the foundation for the final shape. Through precisely designed and manufactured dies, as well as appropriate stamping process parameters, various complex shapes of stamping parts can be produced. Shenzhen Hongrenshuo Precision Technology Co.,Ltd, a globally leading manufacturer of precision connectors, excels in stamping production and processing.

hrs

Difference Between Metal And Plastic 3D Printing

HRS operates a fully integrated, lean manufacturing system designed for high-volume precision stamping. Our process handles 0.3–5mm thick materials with zero-defect rates across six critical stages.

| Stage | Operations | Key Metrics |

| Material Handling | Automated coil feeding (ABB Robotics) with laser leveling for flatness. | Coil throughput: 1,500 coils/hour |

| Stamping | 18 servo presses (50–1,200 tons) using progressive dies for multi-step forming. | Cycle time: 8–45 seconds/part |

| In-line Inspection | 100% vision system (Cognex) with 0.01mm resolution for real-time defect detection. | Defect rejection rate: <0.05% |

| Post-Processing | TIG welding, electroplating, and vibratory finishing for surface optimization. | Surface roughness: Ra ≤0.4μm |

| Packaging | Custom EPE foam packaging with RFID tracking for global shipments. | Lead time: 3–12 days (FOB Shanghai) |

hrs

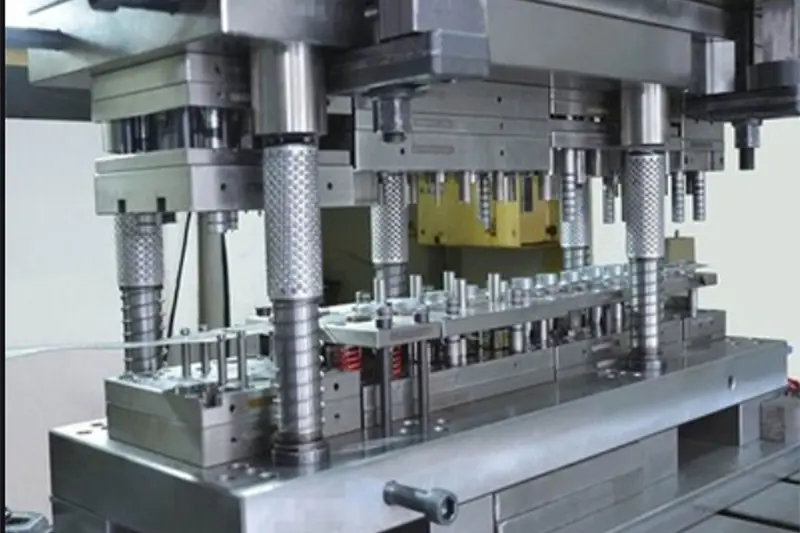

Stamping Die Design & Development

The design and development of stamping dies are crucial for achieving precision and efficiency in production. HRS employs advanced design principles and materials to create high-quality dies.

Aspect | Details |

Design Principles | Incorporate DFM (Design for Manufacturability) principles to optimize production. |

Material Selection | Utilize high-strength, wear-resistant materials such as tool steel. |

Manufacturing Process | Employ precision machining and heat treatment techniques. |

Die Maintenance | Regular maintenance and inspection to ensure longevity and performance. |

Our engineering team delivers precision tooling solutions in 7–45 days from concept to prototype:

Capabilities:

☑ Complex Geometry: 3D-printed tooling cores for micro-features (±0.005mm).

☑ Thermal Management: Induction heating reduces tooling wear by 30%.

☑ Simulation: ANSYS Workbench validates stress distribution in multi-material dies.

Our Equipment & Technology

HRS employs state-of-the-art stamping equipment to ensure precision and efficiency in production.

Our Industry 4.0-enabled facility features state-of-the-art machinery:

| Equipment | Model | Unique Features |

| Stamping Press | Schuler S 5000 | Hydraulic servo control (±0.005mm positioning). |

| Digital Coil Feeder | Schenck CFS 2000 | AI-powered tension adjustment (0.1–5 N/mm²). |

| IoT-enabled CMM | ZEISS Contura G2 | 1μm resolution with automated part indexing. |

| Robotic Deburring | FANUC M6iB | Repeatability ±0.02mm for complex contours. |

Material Application Guide

HRS processes diverse materials for optimal performance:

| Material Type | Grade | Thickness Range | Typical application | HRS Advantage |

| Steel | SPCC/SPHC | 0.5–3mm | Automotive chassis, stamping plates | Cost-effective for high-volume orders. |

| Aluminum | 6061-T6 | 1–2mm | Aerospace panels, consumer electronics | Lightweighting (density 2.7g/cm³). |

| Copper | C1100 | 0.8–1.5mm | Electrical connectors, heat sinks | Highest conductivity (IACS 100%). |

| Stainless Steel | SUS304/316L | 0.2–2mm | Medical instruments, food packaging | Corrosion resistance (ASTM B88). |

Precision & Tolerance Control

HRS achieves ISO 2768-mK compliance with advanced metrology solutions:

| Parameter | Target Tolerance | Measurement Method | Actual Performance | Industry Benchmark |

| Flatness | ≤0.05mm/m | Laser profilometer | ±0.03mm/m | ±0.1mm/m |

| Hole Diameter | ±0.03mm | Go-NoGo gauges | ±0.015mm | ±0.05mm |

| Chamfer Angle | ±0.5° | Coordinate Measuring Machine | ±0.3° | ±1° |

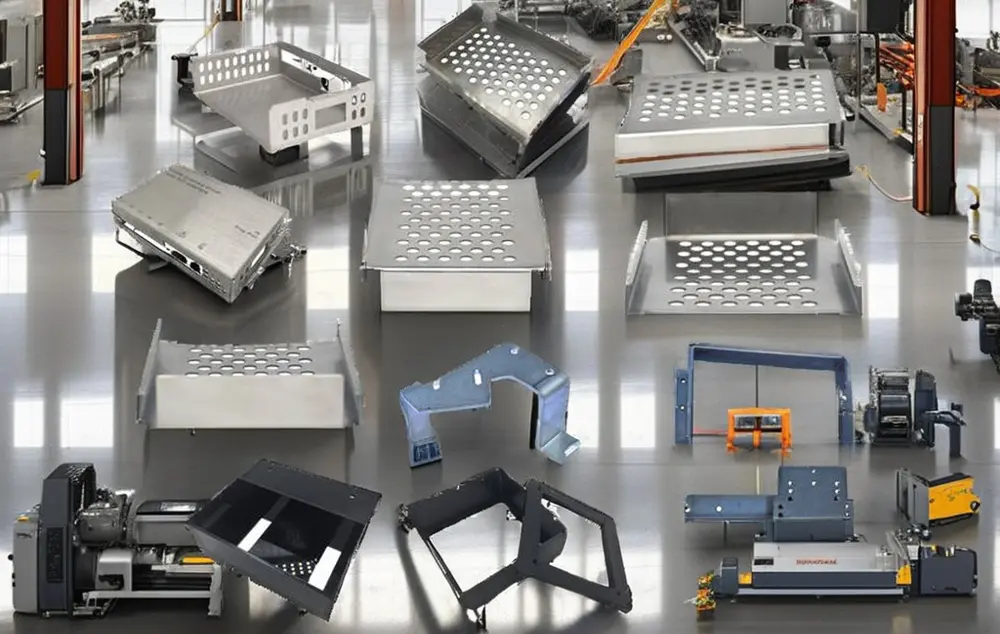

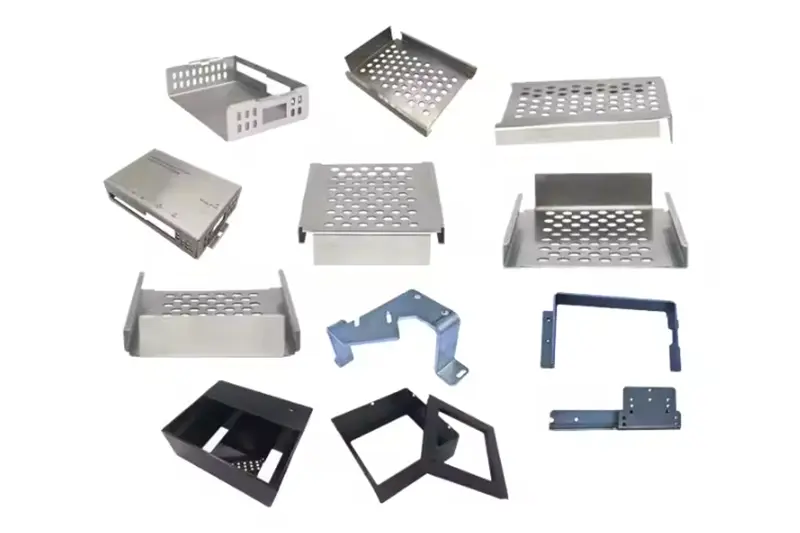

Application Fields

HRS stamped components find applications in a wide range of industries due to their precision and reliability.

| Industry | Application Example |

| Electronics | Connectors, terminals, and other precision components |

| Automotive | Sensor components, electrical connectors |

| Telecommunications | High-speed data connectors |

| Medical Devices | Precision parts for surgical instruments |

| Aerospace | Lightweight, high-strength components |

Characteristics of Stamping Services

☑ High Precision: The dimensional accuracy of stamping parts is guaranteed by the dies, resulting in high stability and interchangeability.

☑ High Efficiency: Stamping production is an efficient processing method. Ordinary presses can produce dozens of stamping parts per minute, while high-speed presses can reach hundreds or even thousands.

☑ Energy and Material Saving: Stamping processing generally does not require hot blanks and, unlike cutting processes, does not require a large amount of metal to be cut away, thus saving both energy and material.

☑ Wide Applicability: Stamping processing is applicable to various metallic materials such as steel plates and aluminum sheets, and can produce stamping parts of various shapes and sizes.

Sign up for our newsletter

At HRS, we are committed to providing our clients with the highest level of precision and quality in every part we machine. Our advanced capabilities, extensive material expertise, and comprehensive surface treatment options make us the ideal partner for all your CNC turning machining needs. Contact us today to learn more about our services and how we can help bring your projects to life.