OEM Services

- Home

- »

- OEM Services

- »

- precision-cnc-milling-product

Advanced Precision CNC Milling Services – China Top CNC Milling/Milled Parts Manufacturer

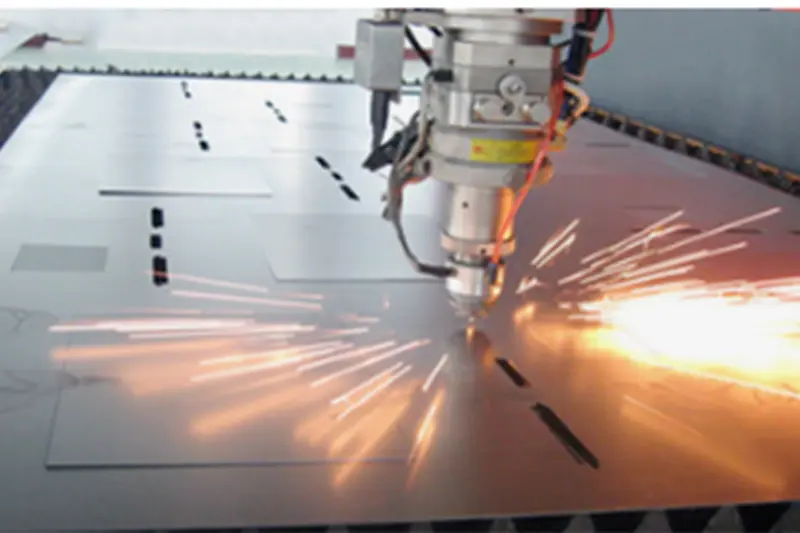

CNC (Computer Numerical Control) milling is a precision machining process that utilizes computer-controlled milling machines to shape work pieces by rotating cutting tools. Our CNC milling services offer a combination of high accuracy, efficiency, and versatility, catering to a wide range of industries and applications.

Processing Advantages

Our CNC milling services offer a combination of high accuracy, efficiency, and versatility, catering to a wide range of industries and applications.

Processing Advantages

Our CNC milling services offer a combination of high accuracy, efficiency, and versatility, catering to a wide range of industries and applications.

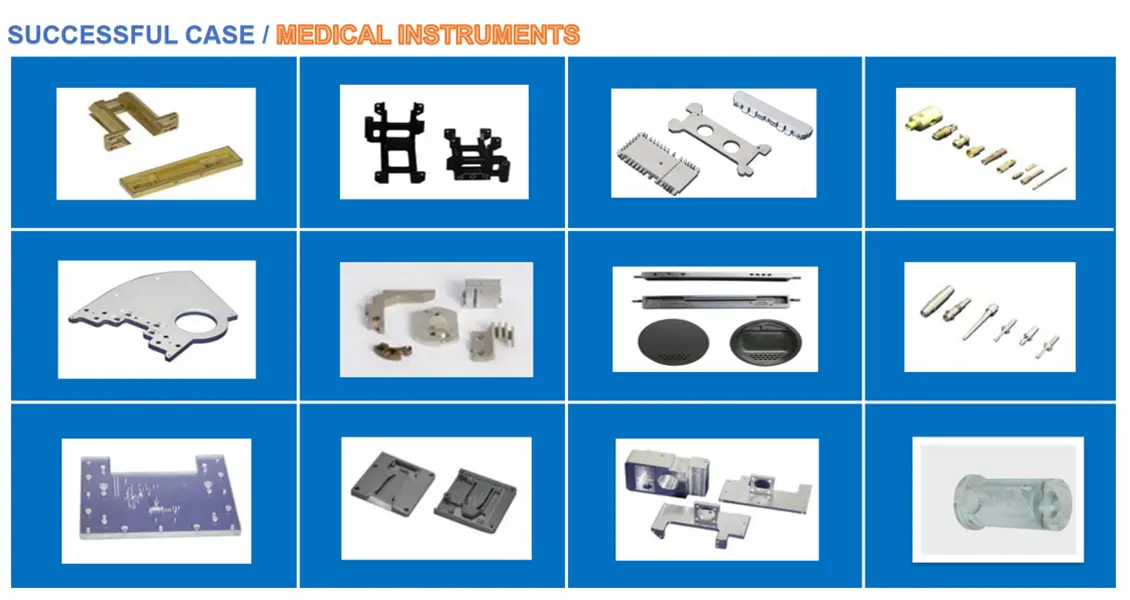

Application Areas

Our CNC milling services are widely utilized across multiple industries:

☑ Mechanical Parts: Key components for various machinery and equipment.

☑ Automotive Components: High-precision parts such as engine components and body structures.

☑ Medical Device Components: Ensuring reliability and safety in medical equipment.

☑ Aerospace Parts: Complex structures like turbine blades and aircraft fuselage components, where precision and strength are paramount.

Conclusion

Our CNC milling services provide a comprehensive solution for precision machining needs. With advantages in accuracy, efficiency, and versatility, combined with strict dimensional tolerances and a range of surface treatment options, we cater to various industries. To illustrate our capabilities further, images and detailed data tables are available upon request. Contact us today for your CNC milling needs.

CNC Milling FAQs

☑ Plane: CNC milling machines can be used to process various planes, including straight lines, arcs and various complex shapes.

☑ Cam: The cam is a common part in machinery, and the CNC milling machine can be used to process various shapes of the cam.

☑ Thread: CNC milling machines can be used to process a variety of threads, including precision threads and special-shaped threads.

☑ Holes: CNC milling machines can be used to process holes of various shapes and sizes, including straight through holes, blind holes, inclined holes, etc.

☑ Curved surfaces: CNC milling machines can be used to process various complex curved surfaces, including spherical surfaces, rotating surfaces and free-form surfaces.

☑ Gears: CNC milling machines can be used to process various gears, including spur gears, helical gears, arc gears, etc.

In short, CNC milling machines can be used to process parts of various shapes and sizes, and have the advantages of high precision, high production efficiency, and stable machining accuracy.

Starting from designing a CNC milling part drawing or geometry with CAD software, then CAM software converts the file to CNC machine program, which can dictate the machine what to do and how to do. CNC milling services apply computerized technique to complete the manufacturing as the following basic production stages:

☑ Designing a CNC Milling CAD model.

☑ Converting the CAD model into a CNC milling program.

☑ Setting up the CNC milling machine.

☑ Cutting small pieces off the block material to obtain approximate shape.

☑ Executing the CNC milling operation with higher precision and accuracy.

Turning operations are performed by rotating the work piece and using a stationary cutting tool, and milling operations are performed by rotating the cutting tool and leaving the workpiece locked in place.

The most common materials used in CNC milling are metals such as brass, Titanium, aluminium or steel, and plastics such as PVC, ABS, polycarbonate and polypropylene.

Due to the spinning motion produced by the CNC milling machine's cutter, the surface finish of CNC machined parts will have visible toolmarks. If you require a smooth, unblemished finish to your part, we recommend choosing a secondary finish: grained finish or powdercoat.

Yes, we offer CNC Turning (Lathe), as well as CNC Machining with 5-Axis, 3-Axis and CNC Routers.