Materials

- Home

- »

- Materials

Materials

In the booming tide of modern manufacturing, injection molding capability, as a key link in the industrial chain, directly determines the quality level of products and the speed of production efficiency. Zhuhai Nuozhouxin Technology Co., Ltd., relying on years of deep cultivation in the field of injection molding, has successfully built a powerful and complete injection molding system, committed to providing high-quality and reliable injection molding solutions for customers in various industries.

Materials

services

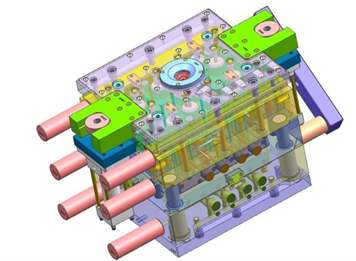

Deeply Engaged in Injection Mold Design, with a Digital Design System to Ensure Mold Quality Assurance

Excellent mold design capabilities need to cover multiple dimensions such as structural rationality, process adaptability, and cost controllability, ensuring strong support for molds from design to production. Moreover, a full 3D design platform (UG/NX + AutoForm) and a PLM data management system have been introduced, enabling “one-click parsing” from customers’ 3D drawings to 3D mold models. Design schemes are traceable and inerrable, ensuring that the standardized reuse rate of molds for the same series of products reaches 60% and reducing customers’ subsequent development costs.

EXPLORE MORE

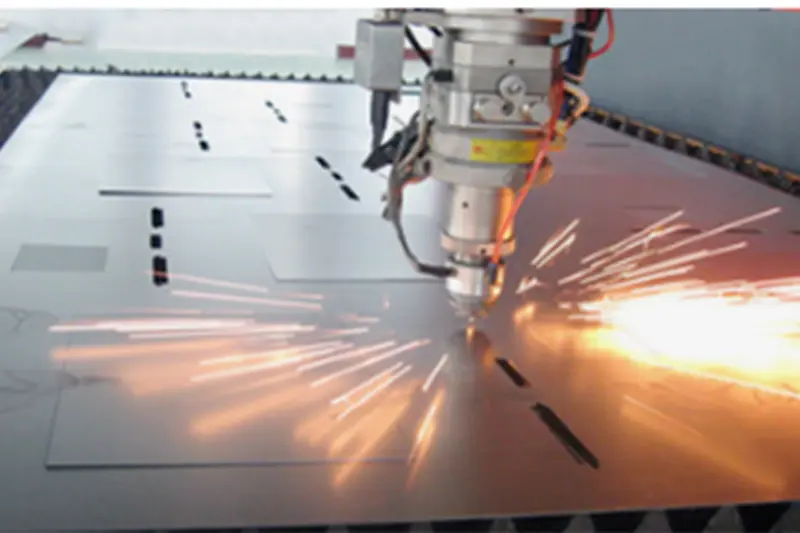

Advanced Equipment Supports Efficient Production

Our company is equipped with a series of internationally leading injection molding equipment (such as Engel/Wittmann), covering different tonnages, which can fully meet the diversified production needs from micro precision parts to large structural parts.

These devices adopt advanced control systems, which can accurately regulate key parameters such as injection speed, pressure, and holding time, ensuring that each injection molding process is stable and reliable. At the same time, the high degree of automation of the equipment has greatly improved production efficiency and effectively shortened the product delivery cycle.

EXPLORE MORE

High-Quality Material Selection: Laying a Solid Foundation for Quality

We fully understand that materials are the cornerstone of the quality of injection-molded products, so we have established an extremely strict material screening mechanism.

- We maintain long-term and stable cooperative relationships with many well-known material suppliers, and the raw materials we use cover various categories such as engineering plastics and general-purpose plastics.

- All raw materials have passed relevant quality certifications. During the material usage process, we will conduct strict inspections on them to ensure that their performance fully meets the production requirements, thus safeguarding product quality from the source.

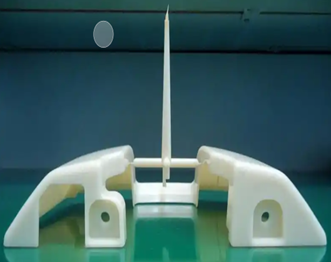

Exquisite Craftsmanship and Technology: Creating Precision Products

The company boasts an experienced technical team, whose members are proficient in various injection molding processes. They can tailor personalized process schemes according to the structural characteristics and performance requirements of products.

Whether it is complex cavity design or high-precision dimension control, we can perfectly achieve it with exquisite craftsmanship and technology. By continuously optimizing process parameters, the injection-molded products we produce not only have high surface finish, but also feature high dimensional accuracy and excellent mechanical properties, fully demonstrating superior quality.

Strict Quality Control: Upholding the Quality Bottom Line

Quality is the lifeline of an enterprise. Our company has established a full-process quality control system, as detailed below:

| Control Processes | Control Content |

| Incoming Raw Material Inspection | Professional quality inspectors conduct strict inspections on incoming raw materials to ensure they meet production requirements. |

| Online Inspection During Production Process | Real-time online inspection is carried out during the production process to promptly detect and resolve problems arising in production. |

| Final Inspection of Finished Products | With the help of advanced testing equipment such as coordinate measuring machines and tensile testing machines, comprehensive inspections are conducted on product indicators including dimensions, strength, and temperature resistance. |

Through full-process quality control, every product delivered from the factory is ensured to meet quality standards.

Wide Application Fields to Meet Diverse Needs

With our excellent injection molding capabilities, our products are widely used in multiple fields, as follows:

- Automotive manufacturing: Such as automotive interior parts, etc.

- Electronics and electrical appliances: Such as electronic connectors, etc.

- Medical devices: Such as medical device housings, etc.

- Household products: Such as household plastic accessories, etc.

With professional technology and rich experience, we meet the personalized needs of customers and contribute to the development of various industries.

Our company always takes customers as the center, continuously improves our injection molding capabilities, and is committed to providing customers with better quality and more efficient injection molding services. We look forward to cooperating with you to create a better future!