OEM Services

- Home

- »

- OEM Services

Materials

HRS is also one professional 3d printing manufacturers in China . We can provide the SLA,SLS,FDM,PLA 3d printing service with different material. As one professional CNC machining services manufacturers in China, HRS can machine all kinds of low cost different CNC machined materials parts. HRS customizes precision CNC Plastic parts according to customer specifications, samples or drawings. We provide all kinds of plastic ABS machining services: CNC milling , drilling , turnings and lathe to complete different geometry shapes and dimensions of the Plastic parts. Our CNC machining Plastic precision parts can undertake surface spraying, electroplating, metal welding, hot pressing and adhesion, widely used in machinery, automobile, electronic appliances, instruments and meters, textile and construction industries. Our technicians have many years experience and knowledge in machine exceptional quality plastic precision parts.

Materials

services

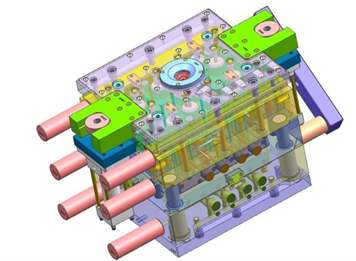

Deeply Engaged in Injection Mold Design, with a Digital Design System to Ensure Mold Quality Assurance

Excellent mold design capabilities need to cover multiple dimensions such as structural rationality, process adaptability, and cost controllability, ensuring strong support for molds from design to production. Moreover, a full 3D design platform (UG/NX + AutoForm) and a PLM data management system have been introduced, enabling “one-click parsing” from customers’ 3D drawings to 3D mold models. Design schemes are traceable and inerrable, ensuring that the standardized reuse rate of molds for the same series of products reaches 60% and reducing customers’ subsequent development costs.

EXPLORE MORE

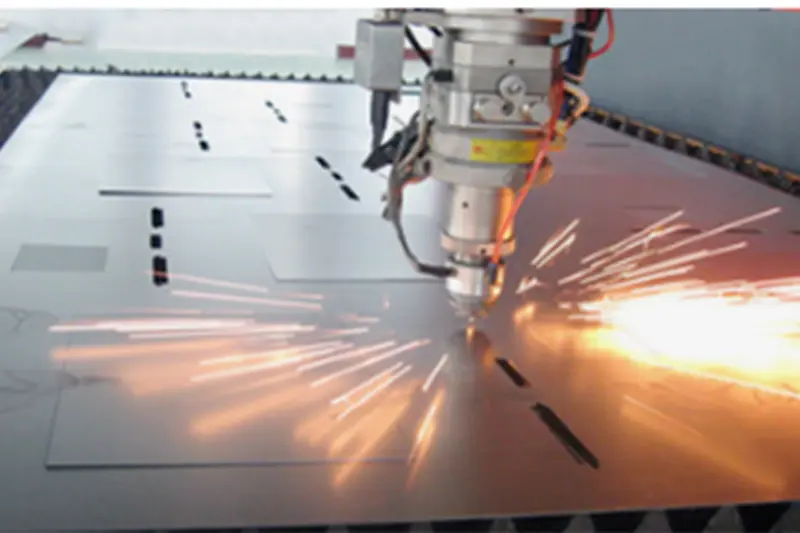

Advanced Equipment Supports Efficient Production

Our company is equipped with a series of internationally leading injection molding equipment (such as Engel/Wittmann), covering different tonnages, which can fully meet the diversified production needs from micro precision parts to large structural parts.

These devices adopt advanced control systems, which can accurately regulate key parameters such as injection speed, pressure, and holding time, ensuring that each injection molding process is stable and reliable. At the same time, the high degree of automation of the equipment has greatly improved production efficiency and effectively shortened the product delivery cycle.

EXPLORE MORE