ABOUT OUR COMPANY

Introduction to Zhuhai Nuozhouxin Technology Co., Ltd.

Zhuhai Nuozhouxin Technology Co., Ltd. was established in June of 2018. has been deeply engaged in the field of precision manufacturing. The company boasts strong strength and excellent capabilities in multiple business areas: its precision machining achieves micron-level accuracy, meeting the stringent requirements of various industries; relying on advanced technologies, the precision component machining for semiconductor equipment ensures the high-quality production of key components; the tooling and fixtures can improve production efficiency and product precision; the mold manufacturing follows high-standard processes, featuring both accuracy and durability; the sheet metal stamping parts are strictly controlled from raw materials to surface treatment; the module assembly service is professional and reliable, guaranteeing product quality; and the injection molding process can precisely control parameters to meet standards.

In the meantime, the company is equipped with advanced equipment and a professional team, and has a strict quality control system. Adhering to the concept of providing customers with high-quality products and services, it has earned a good reputation in many industries such as industrial equipment, automobile manufacturing, semiconductors and electronics.

High Precision Equipments

General Information

| Type | Quantity | Tolerance | |

| Lathe | NAKAMURA-TOME | 2 | 0.005mm |

| Turn-milling machine | 4 | 0.005mm | |

| XKNC | 1 | 0.005mm | |

| Turn-milling machine | 16 | 0.01mm | |

| CITIZEN | 8 | 0.002mm | |

| Turn-milling machine | 1 | 0.01mm | |

| NC Lathes | 1 | 0.005mm | |

| CNC Machining Center | Japan Makino 5 axis | 14 | 0.005mm |

| Japan Makino V55 | 7 | 0.005mm | |

| Japan Makino a51 | 6 | 0.01mm | |

| Japan Brother S700 | 1 | 0.0003mm | |

| Korea Komatch | 1 | 0.001mm | |

| China Taikan 850 | 1 | 0.01mm | |

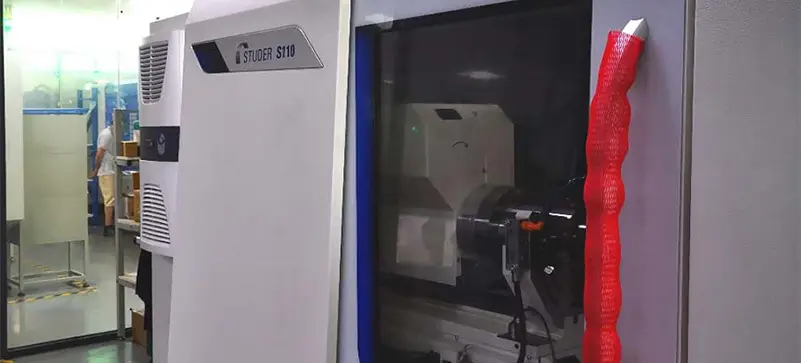

| Grinding | Swiss Studer S110 | 1 | |

| Swiss Studer S200 | 1 | ||

| Swiss Studer ECO 650 | 1 | ||

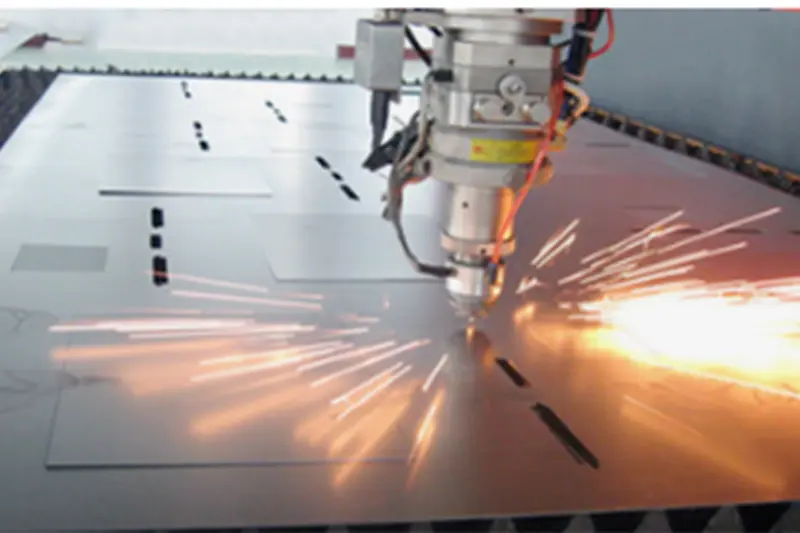

| Sheet metal | HANS Laser machine | 1 | |

| Tailift bending machine | 1 | ||

| EDM | Datie Wire cutting machine | 16 | 0.01mm |

5 Axis CNC Machining Centers

3/4 Axis CNC Machining Centers

☑ Grinding Machine : Swiss Studer

☑ Type:S20 X 1; S110 X 1; ECO 650 X 1

☑ Max diameter : 230 mm (9″)

☑ Tolerance: 0.0003mm

3D Printer equipments

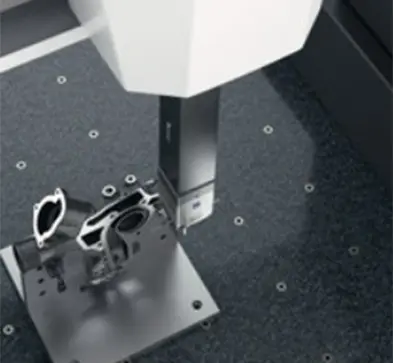

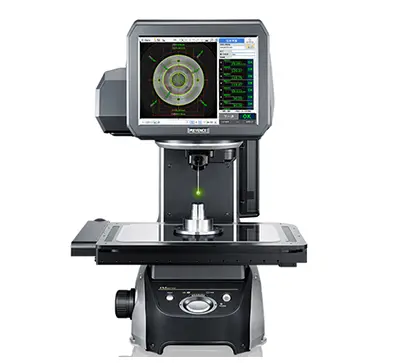

QC Test Equipment hrs

☑ QC Test Equipment:

☑ ZEISS CONTUNE 3 axis measuring system

☑ KEYENCE IM-7000

☑ Mitutoyo measuring instruments

☑ Harness measuring machine

☑ X-Ray chemical analyzer

☑ Profile test machine

Our Products

3/4 Axis CNC Machining Centers

☑ Material:Al 4041

☑ Highlights:0.008mm profile tolerance

☑ Material:Titanium Alloy

☑ Highlights:Tolerance 0.008mm

☑ Material:SUS 316L

☑ Highlights: Surface roughness Ra0.4

☑ Material:Aluminum Alloy

☑ Highlights:300+ dimensions one part

☑ Material:GCr15

☑ Highlights:Key dimension tolerance 0.005mm

☑ Material:Aluminum Alloy

☑ Highlights:thin walls and easy deforming

☑ Material:SUS 304

☑ Highlights:No burrs under 20X microscope

☑ Material:EHS-66

☑ Highlights:One-time fix, surface roughness Ra0.4