In today’s fast-growing manufacturing industry, Precision Cnc Milling Services has become an indispensable technology for many industries. Through highly automated Computer Numerical Control (CNC) technology, Precision CNC Milling is able to manufacture complex shapes and parts with high precision requirements with extreme accuracy and efficiency.

What is Precision CNC Milling?

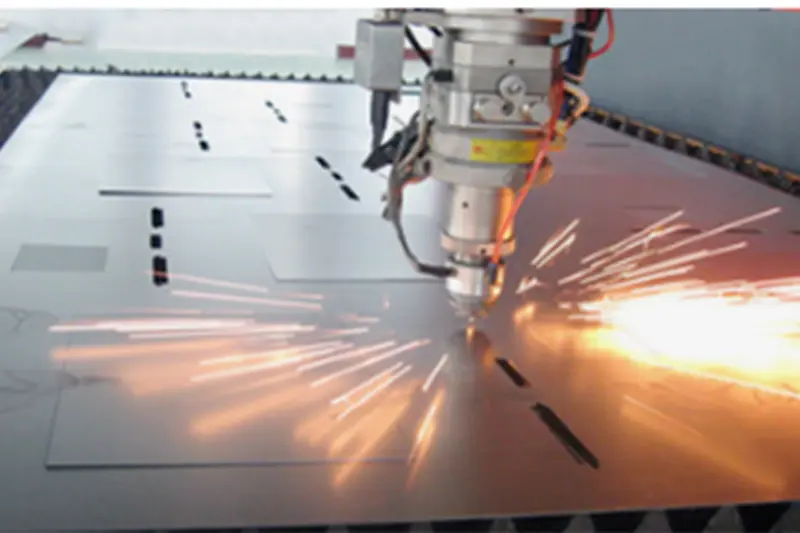

Precision CNC milling is a manufacturing process that uses computer-controlled Machine Tools to cut, shape and drill materials.

Compared to traditional manual milling, CNC milling uses computer-aided design (CAD) software to generate precise machining instructions to ensure that the dimensions, tolerances, and surface quality of parts meet design requirements.

This technology is widely used in aerospace, automotive manufacturing, medical devices and electronic equipment.

Technical Principles and Advantages

The heart of precision CNC milling lies in its high degree of automation and precise control. The machining process starts with a CAD model, where the design data is converted into machine-recognizable commands that control tool movements and machining parameters. Modern CNC milling machines are usually equipped with multi-axis machining capabilities (e.g., 3-, 4- or 5-axis), which enable simultaneous machining in multiple directions, thus reducing the number of repositioning of the workpiece and improving machining efficiency and accuracy.

In addition, the use of High-Speed Milling (HSM) technology further enhances machining accuracy and surface quality. With higher spindle speeds and feed rates, High-Speed Milling reduces thermal deformation and tool wear, resulting in smoother surfaces.

Application Areas

☑ 1. aerospace: manufacturing high precision turbine blades, engine components and structural parts that need to be strong and lightweight under extreme conditions.

☑ 2. medical devices: production of complex shaped medical devices such as orthopedic implants and dental instruments that need to fit perfectly into human tissue.

☑ 3. automotive manufacturing: manufacturing high-precision parts such as engine pistons and transmission gears to ensure automotive performance and reliability.

☑ 4. electronic equipment: production of miniaturized, high-precision electronic components, such as connectors and heat sinks, to meet the stringent size and performance requirements of modern electronic equipment.

Future Development Trends

As technology continues to advance, precision CNC milling services are moving toward higher accuracy, more complex designs and more environmentally friendly machining. For example, some advanced CNC machines have been able to achieve micron or even submicron machining accuracy.

Meanwhile, the rise of smart manufacturing and Industry 4.0 has brought more automated and intelligent solutions for CNC milling.

The wide application and continuous development of precision CNC milling services not only promotes the upgrading of the manufacturing industry, but also provides strong technical support for innovation in various industries.